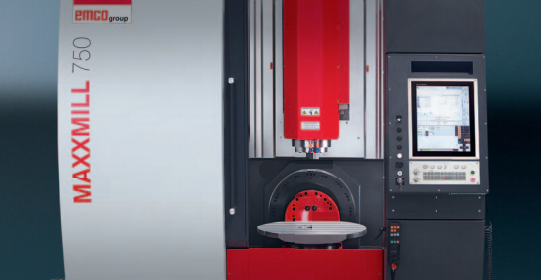

EMCO MAXXMILL 750

Let’s welcome our new EMCO !

The design in cast iron and welded steel guarantees the maximum in rigidity and thermosymmetry. Short

power flows assure the highest precision and an excellent surface quality of the workpiece.

Aided by the 5-sided machining with a single set-up and swivel-rotary table we can mill parts in a clamping area of 750 x 600 mm.

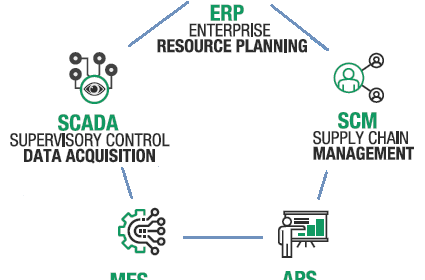

Thanks to the direct interaction between EMCO Apps and the machine control, all data related to Productivity are available at a Glance, great support in our Industry 4.0 approach!