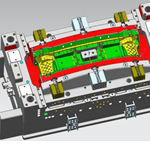

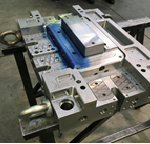

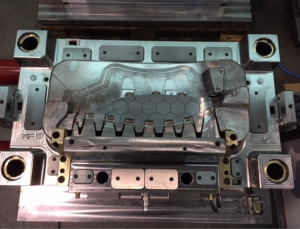

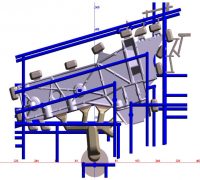

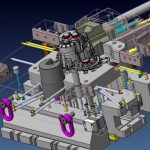

Starting from a geometric model, a drawing, a sample or simply from customers’ ideas or needs, we develop technical solutions for one- or multiple-cavity moulds, injection moulds with hot runners, single-or multiple nozzle, with automatic thread unscrewing; as well as with mould for co-pressing (steel-plastic, plastic-plastic, plastic-plastic-rubber with manual or automatic loading)

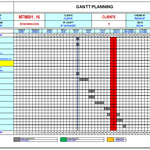

We always perform FEASIBILITY STUDIES to analyse the several technical solutions for each part, taking into consideration shrinkage and deformations of raw material, as well as production needs and all further aspects aimed at optimising the pressing process.

We understand design as a process to develop in close contact with the customer. We provide support in CO-DESIGN to find the best technical solutions and reach high performing tools concepts.